We have the green future firmly in our sights.

Steel production in Saarland is becoming climate neutral.

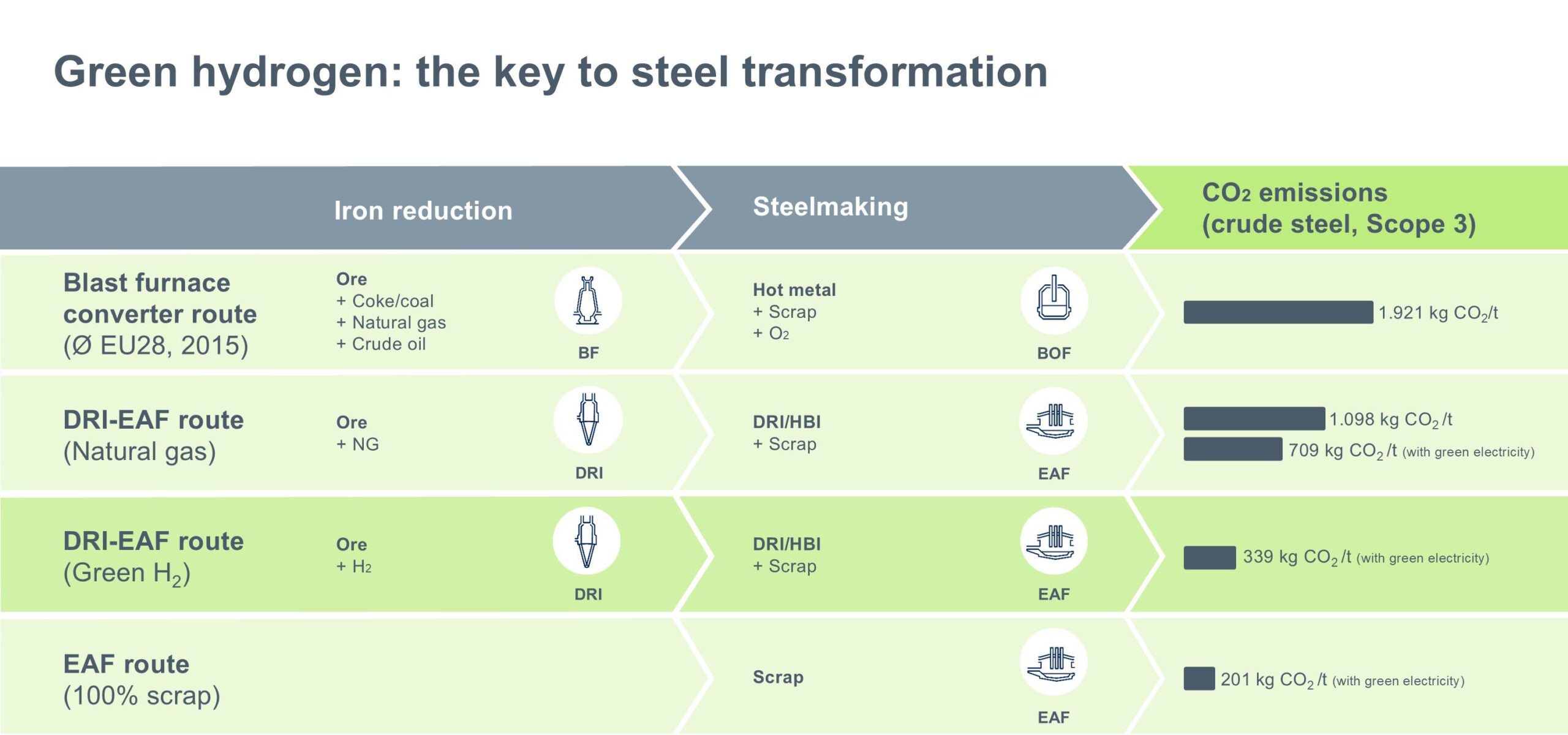

Our aim: carbon neutrality by 2045. As part of the Power4Steel initiative, we’re focusing on using hydrogen, on electric steel production, and on recycling steel scrap. Construction began in 2023 on a direct reduction plant (DRI) and on one electric arc furnace (EAF) each in Dillingen and Völklingen. Production of 3.5 million tons of carbon-reduced products per year is slated to begin in 2028/29. We want to cut carbon emissions by 55 percent by the beginning of the 2030s – that’s 4.8 million tons per year. This means that 70 percent of our production volume will be produced with carbon-reduced methods.

Lorem ipsum dolor sit amet, consectetuer adipiscing elit. Aenean commodo ligula eget dolor. Aenean massa. Cum sociis natoque penatibus et magnis dis parturient montes, nascetur ridiculus mus. Donec quam felis, ultricies nec, pellentesque eu, pretium quis, sem. Nulla consequat massa quis enim. Donec pede justo, fringilla vel, aliquet nec, vulputate eget, arcu. In enim justo, rhoncus ut, imperdiet a, venenatis vitae, justo. Nullam dictum felis eu pede mollis pretium. Integer tincidunt.

Future of Steel Manufacturing – that’s what we are planning

Our path

to climate-neutral steel production: Power4Steel

2020

Hydrogen is used for the first time in Germany – not just in a test plant but on an industrial scale in steel production – in Dillingen, in the blast furnaces of ROGESA Roheisengesellschaft Saar mbH (a joint subsidiary of Saarstahl AG and AG der Dillinger Hüttenwerke).

2022

The Supervisory Boards of SHS – Stahl-Holding-Saar, Saarstahl and Dillinger, the Board of Trustees of Montan-Stiftung-Saar and the management of SHS – Stahl-Holding-Saar decide in December to invest around EUR 3.5 billion – subject to public funding – in the Saarland locations, and thus in the Power4Steel project.

2023

Almost exactly one year later, the path is cleared for the restructuring of steel production on the Saar: The EU Commission approves federal and state government funding of Power4Steel in the amount of EUR 2.6 billion.

2024

Start of construction for a DRI plant and an electric arc furnace (EAF) in Dillingen, and an EAF in Völklingen.

2025

Conclusion of the first hydrogen supply agreement.

2028/29

Planned commissioning of the direct reduction plant (DRI plant) with a capacity of 2.5 million tons in Dillingen. Planned commissioning of one electric arc furnace (EAF) each in Dillingen and Völklingen for production of a total of approx. 3.5 million tons of crude steel per year.

2029

Planned start of production of carbon-reduced steel in Dillingen and Völklingen. In the first phase, 3.5 million tons of crude steel will be produced each year.

By the beginning of the 2030s

We aim to achieve a 55 percent reduction of carbon emissions. That’s 4.9 million metric tons less carbon emitted annually. Dismantling of one blast furnace

By 2045:

Planned construction and commissioning of a third EAF.

From 2045:

Climate-neutral production of around 4.9 million tons of steel.

Photo series